Improve aquaculture operations with OPTiM's IoT solution

Cultivate with AI, IoT, and robotics to improve production quality and quantity, as well as reduce operational costs. Grow your aquaculture facility in unexpected ways.

-

Detect problems early

With an internet-connected, sensor-equipped ICT buoy, changes in water quality can be quickly detected. Furthermore, drone imaging can detect damage in seaweed, such as color changes or bite marks, as well as changes in water color.

-

Improve production quantity and quality

The ICT buoy continuously acquires data through its sensors. The data is analyzed to find the relationships between water quality, labor quantity, and produce quality to help you make smarter decisions.

-

Reduce labor costs

Real-time data can be checked at any time through any smart device or PC, reducing the need for sending staff out into the water for frequent checks of the fish stock or seaweed.

Efficient, effective work with big data management and analysis

Real-time water information with ICT buoys

Various kinds of sensors can be equipped on the ICT buoy to collect various kinds of water data: salinity, temperature, density, and more. Data is continuously collected on the cloud through LPWAN (low power wide are network), so the data can be checked any time, any where.

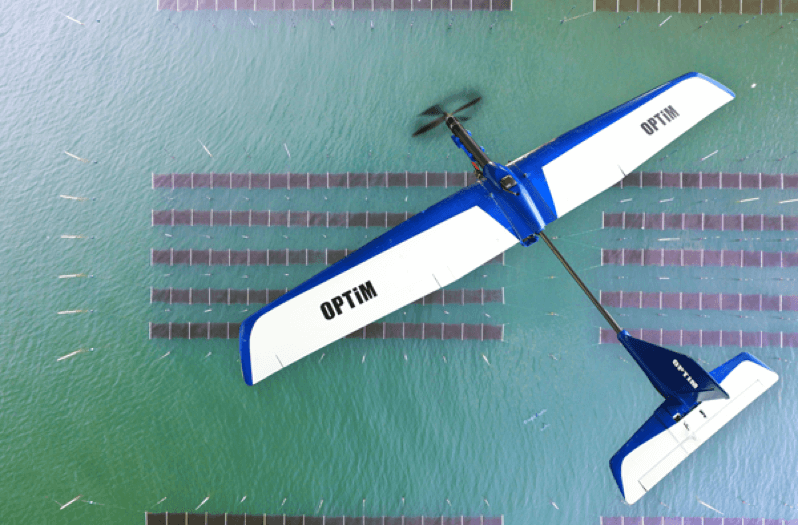

Get a complete view of your water with OPTiM Hawk

Since the OPTiM Hawk drone can fly long distances to get a full aerial picture of the water, there is no need to send staff out in boats for constant inspections. Also, the images can be analyzed to find irregularities, such as red tide, before they grow to serious problems.

Comprehensive aquaculture management with Fishery Manager

Fishery manager, an app for OPTiM Cloud IoT OS, displays all important aquaculture information in one place: weather, water temperature, salinity, pH levels, work logs, and growth data. Fishery Manager can provide all this information in one place, so it’s easy to understand your aquaculture area at a glance. In addition, issues can be handled quickly with alerts that are sent to you when abnormal data is detected.

Optimize your operations with recommendations from AI analysis

OPTiM’s AI links the aquaculture field environment with growth results, and can find the best conditions for your product. The analyzed data includes the state of the water, amount and type of cultivation work, and output statistics. AI can help you uncover insights that humans cannot easily observe.

Key Terms

-

What is LPWA?

LPWA stands for “Low Power Wide Area,” and is a type of wireless communication that can cover several kilometers while only using a small amount of battery power. -

What is an ICT buoy? ICT stands for “Information and Communication Technology,” and an ICT buoy is a buoy that has sensors and communication features that allow it to send collected information to a cloud server.

Prevent Disease, Increase Production Value, and Improve Labor Efficiency with AI, IoT, and Robotics

Point 1

Early disease detection

Improve yield and quality of your product by detecting diseases early and preventing further damage.

Point 2

Optimize labor

Automate routine work, such as data collection, through drones and sensors, allowing workers to focus on more complex tasks.

Point 3

AI-powered operation improvements

AI can uncover more efficient and effective work processes, improving work operations for both experienced and new workers.